When it comes to heavy-duty machinery, precision and reliability are critical. One component that plays a vital role in ensuring smooth rotation and load support in various industries is the slewing bearing. Whether you’re new to industrial equipment or simply want a deeper understanding, this guide will walk you through what slewing bearings are, how they work, and why they are essential—especially in the kind of complex systems developed by companies like Sawei Equipment Technology.

What Is a Slewing Bearing?

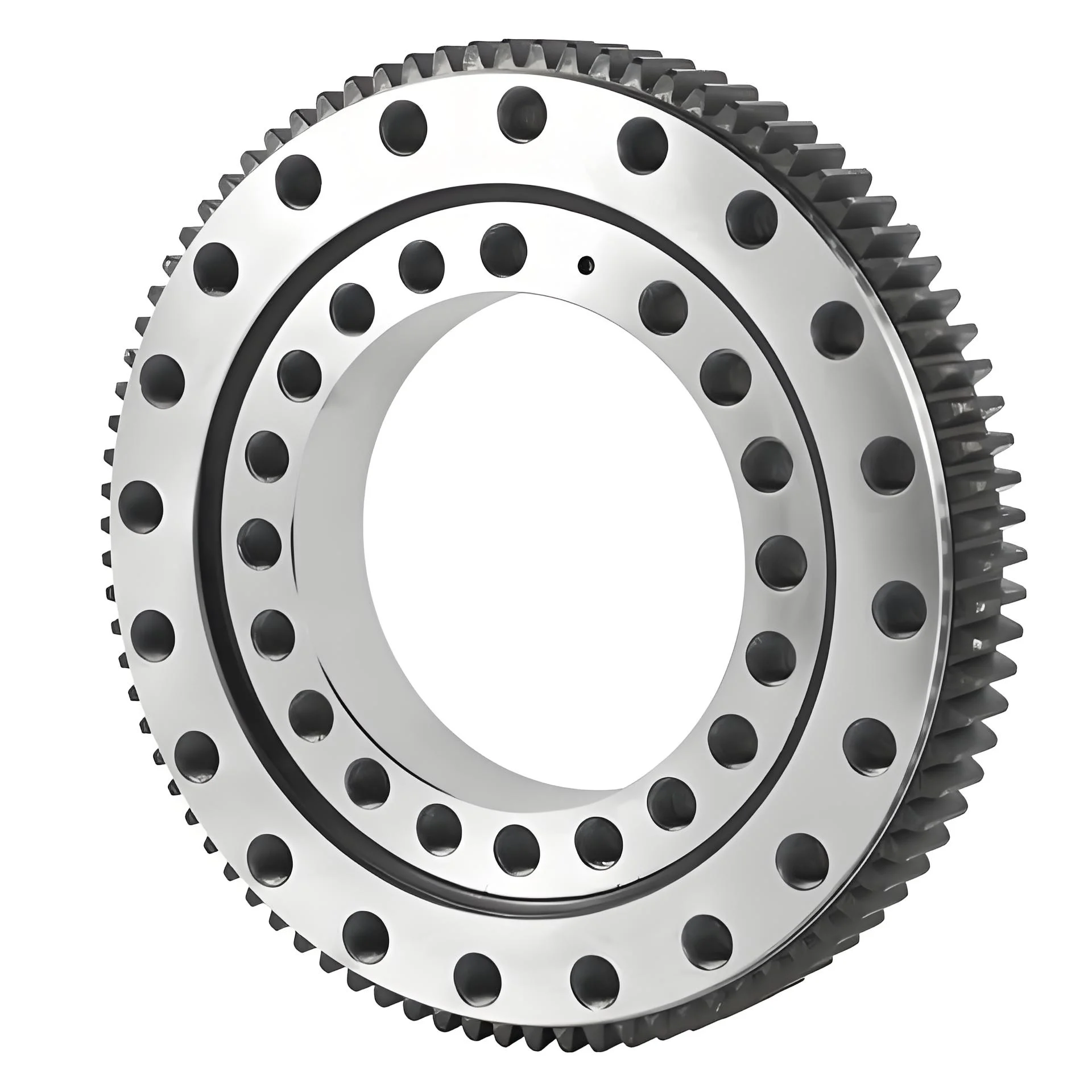

A slewing bearing, sometimes called a slewing ring, is a rotational rolling-element bearing that typically supports a heavy but slow-turning or slow-oscillating load. Unlike traditional bearings, slewing bearings are designed to manage axial, radial, and moment loads all at once. Their large diameter and structural design allow them to perform in extreme conditions, offering smooth and consistent rotational movement for heavy machinery.

Commonly, slewing bearings are found in applications such as cranes, wind turbines, medical equipment, and industrial machinery. They can vary in design—ball bearing, roller bearing, cross roller bearing types—to suit different load demands.

How Do Slewing Bearings Work?

Slewing bearings operate by allowing rotation between two structural parts, often supporting both the rotating and stationary components of machinery. They consist of an inner ring, an outer ring, rolling elements (balls or rollers), and often have gear teeth either on the inner or outer ring to drive rotation.

The design enables them to:

-

Handle multi-directional loads

-

Reduce friction during operation

-

Offer high torque transmission capabilities

-

Extend machinery lifespan with minimal maintenance

Because they need to endure high stress and harsh environments, selecting the right type of slewing bearing is essential for system efficiency.

Slewing Bearings and Sawei Equipment Technology

At Sawei Equipment Technology, high-performance slewing bearings are a key component integrated into our complete process equipment solutions. Specializing in fields such as agrochemical industries (including phosphate chemical engineering, sulfur chemical engineering, ammonium phosphate production, and potassium sulfate compound fertilizers) and biological fermentation industries (such as carbon-containing waste gas and waste oil recycling for industrial environmental protection), Sawei’s projects often demand robust and reliable mechanical systems.

In fertilizer plants or bio-recycling facilities, equipment must endure heavy loads, constant rotation, and harsh chemical exposure. Slewing bearings help ensure that large-scale machinery like reactors, dryers, scrubbers, and agitators operate smoothly and reliably under these demanding conditions. Sawei’s professional engineering teams understand the critical importance of selecting the right slewing bearing to match each project’s unique operational requirements.

Why Choosing the Right Slewing Bearing Matters

In complex process systems like those Sawei designs, selecting the wrong bearing can lead to:

-

Equipment downtime

-

Increased maintenance costs

-

Shorter service life

-

Safety risks

Key factors to consider when choosing a slewing bearing include:

-

Load capacity (axial, radial, and moment loads)

-

Operating environment (temperature, moisture, chemical exposure)

-

Rotation speed

-

Material and coating requirements

By carefully evaluating these elements, Sawei ensures optimal performance and longevity for all its engineering solutions.

Final Thoughts

Understanding slewing bearings is fundamental for anyone involved in industrial equipment, especially in sectors like agrochemicals and environmental recycling where durability and reliability are non-negotiable. With deep industry expertise and a commitment to innovation, Sawei Equipment Technology continues to deliver cutting-edge solutions that incorporate critical components like slewing bearings to drive efficiency, safety, and sustainability in modern industry.

www.swasps.com

Jiangsu Sawei Equipment Technology Co., Ltd.

More Stories

ATLAS COPCO 3002600320 PACKAGING KIT

Simple Structure and Principle of Radial Extrusion Molds

Kangchi Fastener Unveils Innovative Flange Nut Design to Enhance Industrial Efficiency