Relays play a crucial role in various industries, serving as essential components in electrical systems. When it comes to relays, two primary types dominate the market: solid state relays (SSRs) and mechanical relays. While both serve the purpose of controlling electrical circuits, they differ significantly in terms of construction, operation, and performance. In this article, we will delve into the intricacies of solid state and mechanical relays, highlighting their key differences and helping you make informed decisions for your specific application.

- Construction and Working Principle:

Solid State Relays:

Solid state relays, as the name suggests, utilize solid-state components, such as semiconductors, to perform switching operations. They consist of an input control circuit, an optocoupler, and a power switching device, typically a thyristor or a triac. The absence of moving parts in SSRs ensures enhanced reliability and longevity. These relays operate by controlling the current flow through the optocoupler, which triggers the power switching device, allowing or blocking the current flow in the output circuit.

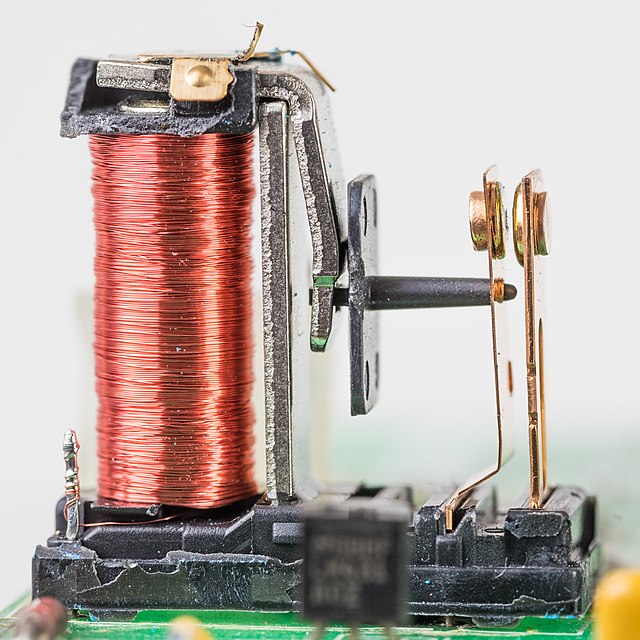

Mechanical Relays:

On the other hand, mechanical relays employ electromechanical components, including coils, armatures, and contacts. When an electrical signal is applied to the coil, it generates a magnetic field, attracting the armature and closing the contacts. This physical movement of components enables the electrical circuit to be completed or interrupted. Mechanical relays are known for their robustness and ability to handle high currents and voltages.

- Performance and Advantages:

Solid State Relays:

Solid state relays offer several advantages over their mechanical counterparts. Firstly, SSRs have faster switching speeds, typically in the range of microseconds, ensuring precise control and response in applications that require rapid switching. Secondly, SSRs exhibit no contact bounce, a common issue in mechanical relays that can lead to signal distortion or malfunction. Additionally, SSRs are noiseless, generate minimal heat, and have no mechanical wear and tear, resulting in improved reliability and reduced maintenance requirements.

Mechanical Relays:

Mechanical relays excel in certain areas where SSRs may fall short. They can handle higher current and voltage ratings, making them suitable for heavy-duty applications. Mechanical relays also provide better isolation between the input and output circuits, ensuring enhanced protection against voltage spikes or surges. Moreover, mechanical relays are generally more cost-effective than SSRs, making them a preferred choice in budget-conscious projects.

- Applications:

Solid State Relays:

Solid state relays find extensive use in industries that demand precise control, such as automation, robotics, and medical equipment. Their fast response time, compact size, and ability to switch AC and DC loads make them ideal for applications involving temperature control, motor drives, lighting control, and power distribution systems.

Mechanical Relays:

Mechanical relays are commonly employed in applications that require high power switching, such as industrial machinery, power distribution, and automotive systems. Their ability to handle large currents and voltages makes them suitable for controlling heavy loads, including motors, heaters, and lighting fixtures.

Conclusion:

In summary, solid state relays and mechanical relays differ significantly in terms of construction, operation, and performance. Solid state relays offer advantages such as faster switching speeds, no contact bounce, and improved reliability, making them suitable for precise control applications. On the other hand, mechanical relays excel in handling high currents and voltages, providing better isolation, and being more cost-effective. Understanding the differences between these relay types is crucial in selecting the most appropriate option for your specific application, ensuring optimal performance and reliability.

More Stories

ATLAS COPCO 3002600320 PACKAGING KIT

Simple Structure and Principle of Radial Extrusion Molds

Kangchi Fastener Unveils Innovative Flange Nut Design to Enhance Industrial Efficiency