In the modern world of industrial manufacturing, the creation of high-quality pipeline systems is fundamental to a range of industries, from oil and gas to water supply and infrastructure development. One of the most advanced methods for producing robust, reliable, and efficient pipes for such applications is through the use of HF (High Frequency) tube mills. These machines have revolutionized the way pipes are made, enhancing efficiency, product quality, and production speed. This article Mazs delves into the significance of HF tube mills in the pipe manufacturing industry, examining their

process and applications in pipeline systems.

The HF Tube Mill Process

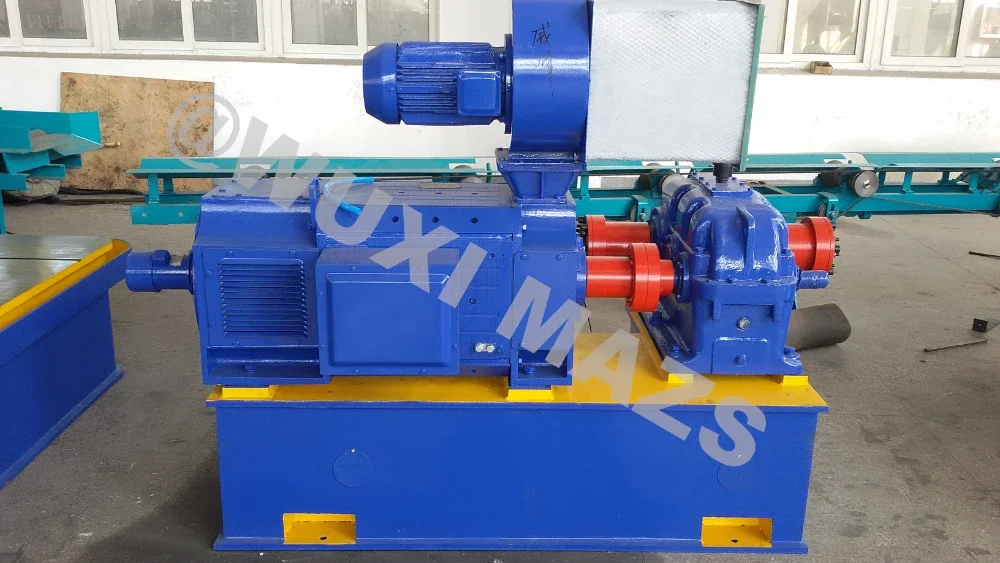

The HF tube mill process is central to the manufacturing of high-quality pipes that serve numerous industries, from transportation and energy to construction. The HF tube mill is a sophisticated piece of equipment that uses high-frequency currents to heat and weld metal strips into seamless pipes. These pipes are not only strong but are also cost-efficient, as the process eliminates the need for additional materials, such as filler metal, and reduces labor costs by automating key stages of production.

In an HF tube mill, the process begins with a cold-rolled steel strip that is uncoiled and fed into a series of rollers. These rollers progressively shape the strip into a tubular form, guiding it through several stages of shaping. As the strip reaches the final bend, high-frequency currents are introduced into the edges of the strip, causing localized heating that allows the edges to fuse together without the need for welding rods or other additional materials. The result is a strong, continuous weld that forms the foundation of the tube. The tube is then cooled and cut into lengths as required. This process provides a reliable and efficient method for manufacturing pipes with excellent structural integrity, uniform thickness, and precise dimensions.

The HF tube mill process has been refined over decades, with innovations that improve the precision of welding, the speed of production, and the quality of the final product. HF tube mills are crucial to industries where pipe durability and pressure resistance are paramount, including those that require long pipelines or systems that need to operate under harsh conditions.

Applications of HF Tube Mills in Pipeline Systems

HF tube mills produce pipes for a wide range of industries, and each sector relies on specific qualities and attributes in the finished products. These applications can vary greatly depending on the pipe's purpose, the environment in which it will operate, and the materials it will transport. HF tube mills are indispensable in producing pipes for both standard and specialized applications.

Oil and Gas Pipelines

The oil and gas industry is one of the largest users of HF tube mills, as the pipes produced by these mills are critical for transporting crude oil, natural gas, and other substances across long distances. These pipes must be able to withstand high pressures, extreme temperatures, and corrosive environments. HF tube mills produce pipes with strong welds, uniform thickness, and high resistance to corrosion, making them ideal for the harsh conditions of oil and gas pipelines.

Water Supply Systems

Municipal water supply systems also rely on HF tube mills to produce pipes that transport clean water to homes, businesses, and industries. The pipes used in these systems need to be durable, corrosion-resistant, and capable of withstanding varying pressures. HF tube mills produce pipes that meet the stringent standards for water safety, helping to ensure a reliable and safe water supply.

Chemical Processing

In the chemical processing industry, pipes must be capable of handling highly corrosive substances, high pressures, and fluctuating temperatures. HF tube mills are used to produce pipes that are resistant to chemical degradation, corrosion, and physical stress. This is particularly important in industries like pharmaceuticals, petrochemicals, and industrial chemicals, where pipe integrity is essential for safety and efficiency.

Construction and Infrastructure

HF tube mills also play a crucial role in the construction industry, where they produce pipes for drainage, sewage systems, and structural applications. These pipes are designed to handle both the mechanical stresses of construction projects and environmental factors such as water exposure and chemical reactions. The strength and reliability of the pipes produced by HF tube mills ensure the durability of construction and infrastructure projects.

HF tube mills have transformed the way pipes are produced for various industries, offering significant advantages in terms of efficiency, performance, and quality. Their ability to manufacture high-strength, seamless pipes with precise specifications makes them indispensable for applications in oil and gas, water supply, chemical processing, and infrastructure development. With continuous advancements in technology, HF tube mills will remain at the forefront of pipe manufacturing, contributing to the construction of safer, more efficient, and more reliable pipeline systems worldwide.

https://www.mazsmachine.com/Enhancing-Pipeline-Manufacturing-HF-Tube-Mills-in-Modern-Industry.html

https://www.mazsmachine.com/MA76E-127-HF-Tube-Mill.html

www.mazsmachine.com

WUXI MAZS MACHINERY GROUP

More Stories

ATLAS COPCO 3002600320 PACKAGING KIT

Simple Structure and Principle of Radial Extrusion Molds

Kangchi Fastener Unveils Innovative Flange Nut Design to Enhance Industrial Efficiency