Capacitors are fundamental electronic components that store and release electrical energy. They play a crucial role in a wide range of applications, from power supply systems to electronic devices. Understanding the basic types of capacitors is essential for engineers, hobbyists, and anyone interested in electronics. In this article, we will delve into the diverse world of capacitors, exploring their various types and applications.

- Ceramic Capacitors:

Ceramic capacitors are the most common and widely used type. They are known for their small size, low cost, and high capacitance values. These capacitors are made of ceramic materials and are available in different classes, such as Class 1 and Class 2. Class 1 ceramic capacitors offer high accuracy and stability, making them suitable for applications requiring precise capacitance values. On the other hand, Class 2 ceramic capacitors provide higher capacitance values but with lower accuracy, making them ideal for filtering and decoupling applications. - Electrolytic Capacitors:

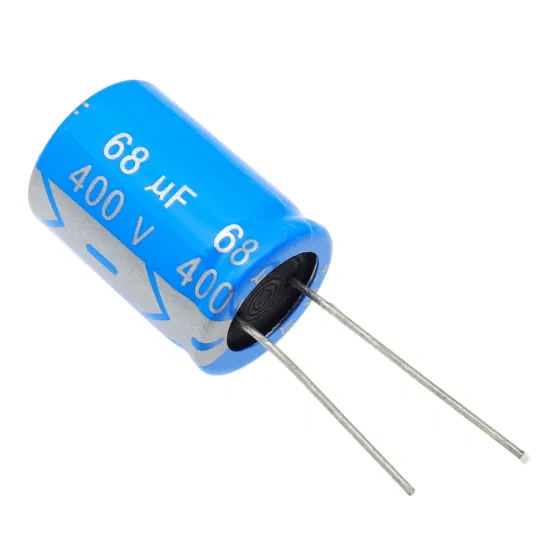

Electrolytic capacitors are polarized capacitors that offer high capacitance values. They are commonly used in power supply circuits and audio systems. Aluminum electrolytic capacitors and tantalum electrolytic capacitors are two popular subtypes. Aluminum electrolytic capacitors are cost-effective and provide high capacitance values, while tantalum electrolytic capacitors offer smaller sizes and better stability. However, it is important to note that electrolytic capacitors have limited voltage ratings and a shorter lifespan compared to other types. - Film Capacitors:

Film capacitors are known for their excellent electrical properties and reliability. They are made of a thin plastic film as the dielectric material. Film capacitors can be further classified into several subtypes, including polyester film capacitors, polypropylene film capacitors, and metalized film capacitors. Polyester film capacitors are widely used in general-purpose applications, while polypropylene film capacitors are preferred for high-voltage and high-frequency applications. Metalized film capacitors offer self-healing properties, making them suitable for demanding applications where reliability is crucial. - Tantalum Capacitors:

Tantalum capacitors are compact and offer high capacitance values in a small package. They are widely used in portable electronic devices, telecommunications equipment, and medical devices. Tantalum capacitors have excellent stability, low leakage current, and high reliability. However, they are more expensive compared to other types of capacitors. - Supercapacitors:

Supercapacitors, also known as ultracapacitors or electric double-layer capacitors (EDLCs), are energy storage devices that bridge the gap between traditional capacitors and batteries. They offer high energy density and can store and release energy rapidly. Supercapacitors find applications in hybrid vehicles, renewable energy systems, and electronic devices requiring quick energy bursts.

Conclusion:

Capacitors are essential components in modern electronics, and understanding their basic types and applications is crucial for designing and troubleshooting electronic circuits. In this article, we explored the diverse world of capacitors, including ceramic capacitors, electrolytic capacitors, film capacitors, tantalum capacitors, and supercapacitors. Each type has its unique characteristics and applications, allowing engineers and hobbyists to choose the most suitable capacitor for their specific needs. By harnessing the power of capacitors, we can continue to drive innovation and advance technology in various industries.

More Stories

AI Smart Glasses with AR Integration: Explore a New Reality

Smart Dynamic Cycling Helmet with Warning Lights for Real Roads

Dual Gas Spring Monitor Arms: The Perfect Solution for Multi-Screen Setups