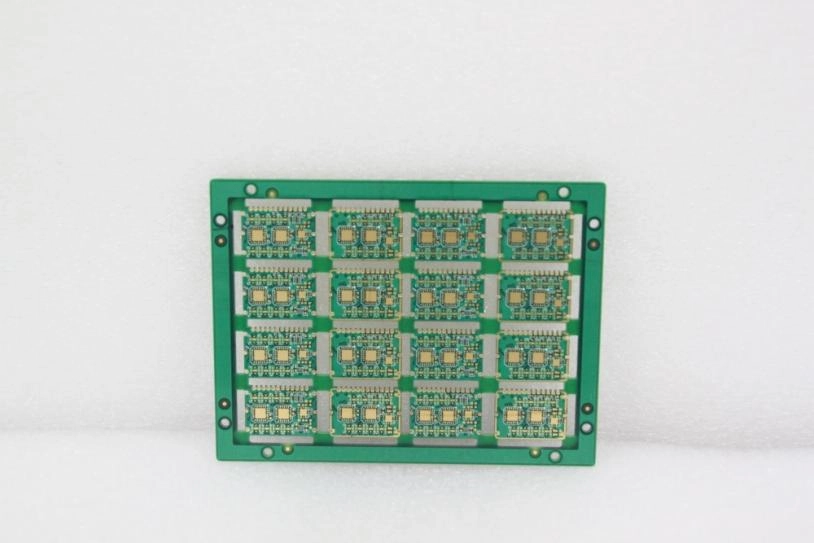

Every breakthrough in electronics—whether it's a new medical device, a next-generation smartphone, or a reliable automotive controller—depends on a critical foundation: the printed circuit board (PCB). PCBs do far more than simply hold components in place. They distribute power, transmit signals, and ensure that every function operates as designed. While mass-produced boards may work for simple applications, true progress requires something more specialized. That's where custom PCB fabrication comes in. By tailoring materials, stack-ups, and layouts to match the exact needs of each project, custom fabrication makes it possible to achieve performance, reliability, and manufacturability that generic boards cannot deliver. SprintPCB has become a global partner for companies that need this level of precision. With expertise spanning prototyping to volume production, plus a strong foundation of certifications and engineering support, SprintPCB offers a complete ecosystem for custom PCB fabrication.

Why Custom PCB Fabrication Is Essential

1. Design Freedom That Matches Application Needs

Every industry has different requirements. A wearable device designer may need a lightweight, flexible PCB, while aerospace manufacturers require rigid boards capable of handling extreme vibration and temperature. Custom PCB fabrication allows engineers to choose the right substrates, copper thickness, and dimensions to match these needs exactly. This flexibility ensures that final products meet not just functional expectations, but also the unique mechanical and environmental challenges of their industries.

2. Performance Gains That Drive Innovation

Signal integrity, thermal control, and power management are often bottlenecks in product design. For instance:

-

In 5G or radar systems, low-loss laminates are necessary to preserve signal quality.

-

In high-power LED lighting, metal-core PCBs prevent heat buildup and extend product life.

-

In consumer electronics, compact multilayer boards deliver functionality in minimal space.

These performance advantages are only achievable through custom PCB fabrication, where every material and manufacturing step is selected for maximum efficiency.

3. Manufacturability and Cost Control

A design that looks perfect on paper may not be practical on the production line. SprintPCB applies design-for-manufacturability (DFM) reviews to ensure that layouts can be built efficiently without sacrificing performance. By reducing unnecessary layers, optimizing panelization, and using cost-effective finishes, SprintPCB helps clients achieve their technical goals while staying within budget.

4. Compliance with Industry Standards

Medical, automotive, and aerospace sectors impose strict certification requirements. A medical board may need ISO 13485 compliance for traceability, while automotive electronics rely on IATF 16949 for safety in high-vibration environments. Custom PCB fabrication ensures these needs are built into the process, so the boards not only function but also comply with global regulations.

SprintPCB: Certified Confidence in Custom PCB Fabrication

Reliability in electronics begins with compliance. Certifications prove that a manufacturer doesn't just talk about quality but actively demonstrates it. SprintPCB's portfolio includes:

-

ISO 9001: Robust quality management systems for consistency.

-

UL Certification: Global safety standards for performance assurance.

-

RoHS Compliance: Environmentally friendly production free from restricted substances.

-

QC080000: Specialized control of hazardous substances in processes.

-

IATF 16949: Automotive-grade reliability under extreme operating conditions.

-

ISO 13485: Medical-grade safety and quality management.

-

AS9100: Aerospace-level standards for mission-critical electronics.

This breadth of certifications is what makes SprintPCB stand out. Many PCB vendors may offer manufacturing capabilities, but without such comprehensive compliance, their boards cannot be used in regulated industries. SprintPCB bridges this gap, offering not just production capacity, but the assurance that every custom PCB fabrication project will meet international safety and reliability benchmarks.

Engineering Support: SprintPCB's True Differentiator

The difference between an average PCB supplier and a strategic partner lies in engineering support. SprintPCB positions itself as more than a manufacturer—it is an engineering-focused collaborator.

Here's how SprintPCB makes an impact:

-

Design-for-Manufacturability (DFM) Reviews: SprintPCB experts analyze layouts for efficiency, recommending changes that improve yields and reduce costs.

-

Material Expertise: Guidance on choosing high-frequency laminates, copper thicknesses, or metal cores tailored to performance demands.

-

Cost Reduction Strategies: Advice on simplifying stack-ups, selective finishes, or optimized panel usage to save costs without reducing quality.

-

File Verification and Corrections: Thorough checks of Gerber and CAD files to eliminate design flaws before production begins.

This proactive support reduces the risk of rework, shortens project timelines, and ensures that custom PCB fabrication delivers maximum value from day one.

SprintPCB vs. Traditional Suppliers

What makes SprintPCB unique in the crowded PCB market?

-

Engineering-Driven Approach: Most fabricators focus only on fulfilling orders. SprintPCB actively participates in the design stage to ensure manufacturability and cost-effectiveness.

-

Full-Spectrum Certifications: From automotive to aerospace, SprintPCB's certifications open doors to industries that demand strict compliance.

-

Customer-Centric Service: Dedicated account managers and rapid response times mean every client receives tailored attention.

-

End-to-End Solutions: SprintPCB covers the entire lifecycle—from prototypes to small and medium runs, assembly, logistics, and EMS services.

-

Sustainable Cost Efficiency: Lean processes and smart engineering ensure long-term savings without compromising quality.

Choosing SprintPCB isn't just about buying PCBs—it's about partnering with a company that supports growth, compliance, and innovation.

Conclusion: Innovation Requires the Right Partner

In today's electronics landscape, where every millimeter of space and every watt of energy matters, custom PCB fabrication is no longer optional—it's essential. Generic boards cannot meet the demands of industries that require performance, safety, and compliance. SprintPCB delivers more than boards. With comprehensive certifications, deep engineering expertise, and customer-first service, SprintPCB provides a complete framework for innovation. From concept to production, it ensures that clients have not only reliable PCBs but also the confidence that their products will succeed in competitive markets. For companies looking to accelerate development, reduce costs, and meet global standards, SprintPCB is the clear partner of choice. With SprintPCB, custom PCB fabrication becomes not just a process, but a pathway to long-term success.

https://www.sprintpcb.net/pcb/

www.sprintpcb.net

SprintPCB

More Stories

AI Smart Glasses with AR Integration: Explore a New Reality

Smart Dynamic Cycling Helmet with Warning Lights for Real Roads

Dual Gas Spring Monitor Arms: The Perfect Solution for Multi-Screen Setups