Explosion proof flexible couplings are critical components for ensuring safe operation in environments where flammable gases, vapors, or dust create explosion hazards. Unlike standard couplings, these devices are specifically engineered to prevent sparks, friction, and other ignition sources that can trigger catastrophic accidents.

Understanding the Risk

Mechanical couplings transmit torque between rotating shafts, but conventional designs can generate sparks or heat due to:

-

Metal-to-metal contact under high load

-

Misalignment between connected shafts

-

Sudden torque overload or vibration

-

Friction caused by wear or insufficient lubrication

In hazardous environments, even a small spark can ignite combustible dust or gas, making preventive measures essential.

Explosion-Proof Design Features

1. Non-Sparking Materials

Explosion proof flexible couplings use specialized materials such as stainless steel alloys, high-grade composites, or coatings that minimize metal-on-metal friction. These materials are carefully selected to resist wear and prevent spark generation even under high stress.

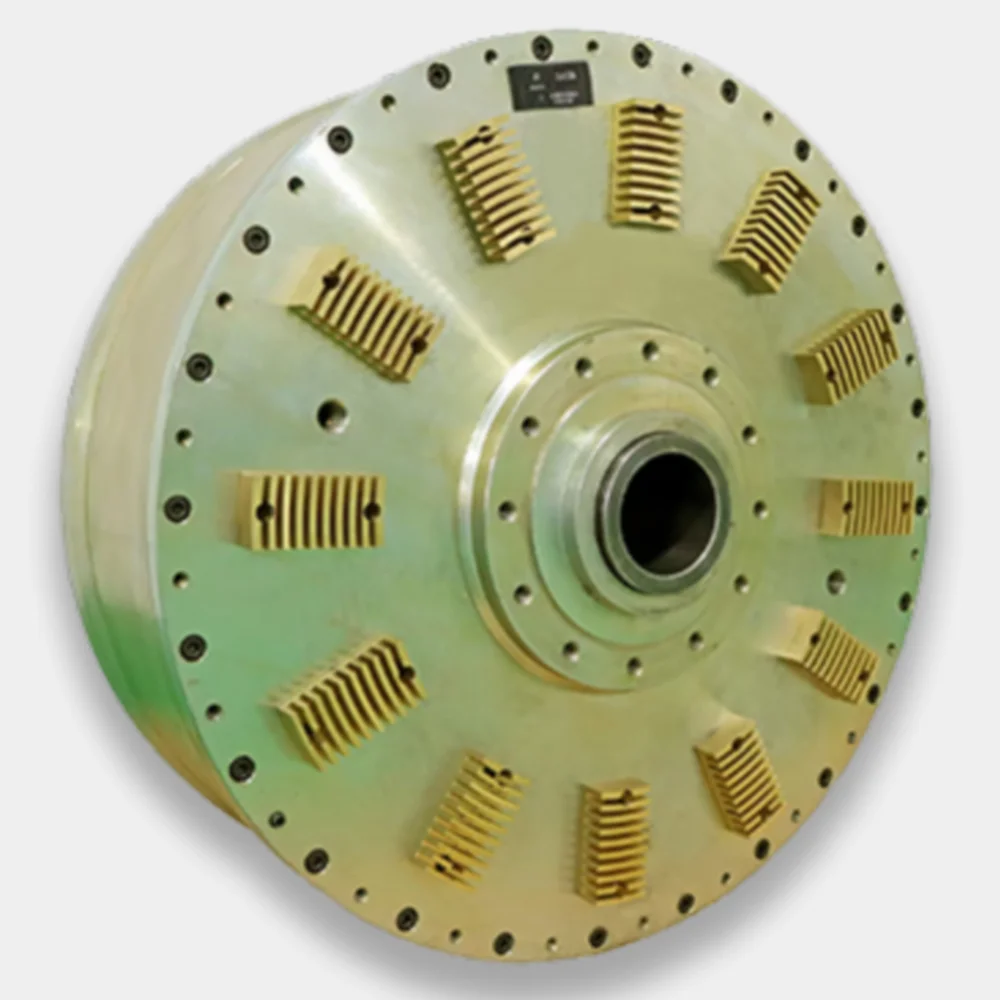

2. Flexible and Magnetic Torque Transmission

Many explosion-proof couplings integrate flexible or magnetic elements to absorb misalignment, vibration, and shock loads. This prevents sudden mechanical impacts that could produce sparks:

-

Flexible torsion elements allow small angular or axial misalignments without metal contact.

-

Magnetic torque transmission provides contactless power transfer, fully eliminating friction-based spark risks.

3. Torque Limiting Mechanisms

Sudden torque spikes can lead to mechanical impacts, heating, or friction—all potential ignition sources. Explosion-proof couplings often include torque-limiting features that prevent overloads, ensuring smooth, controlled torque transmission.

4. Isolation and Enclosure Design

Explosion-proof couplings may also incorporate sealed housings or protective enclosures:

-

Dust and gas exclusion prevents flammable particles from entering moving parts.

-

Controlled movement reduces vibration and friction heat, further minimizing ignition risk.

5. Compliance with Hazardous Area Standards

These couplings meet strict international safety standards for low-spark operation, ensuring safe mechanical performance in high-risk environments.

Applications Where Spark Prevention Is Critical

Explosion proof flexible couplings are widely used in equipment where low fire risk is essential:

-

Mining – Coal conveyors, crushers, and pumps operating in dust-laden mines.

-

Oil & Gas – Compressors, pumps, and drilling machinery in gas-rich environments.

-

Chemical Processing – Reactors, agitators, mixers, and chemical dosing equipment handling volatile chemicals.

Through material selection, flexible or magnetic torque transmission, torque limiting, and isolation design, explosionproof flexible couplings significantly reduce the risk of sparks and ignition. These couplings are indispensable for mechanical and electrical systems operating in hazardous atmospheres, ensuring both safety and reliability.

https://www.magicmag-tech.com/how-explosion-proof-flexible-couplings-prevent-sparks-and-ignition-ris

SHANGHAI GAOLV E&M Technology Co.,Ltd.

More Stories

Why Titanium Pressure Vessels Are the Ideal Solution for Critical Applications

ATLAS COPCO KIT OIL SEPARATOR 29010085

How Disposable Shoe Cover Machines are Revolutionizing Hygiene in Various Industries